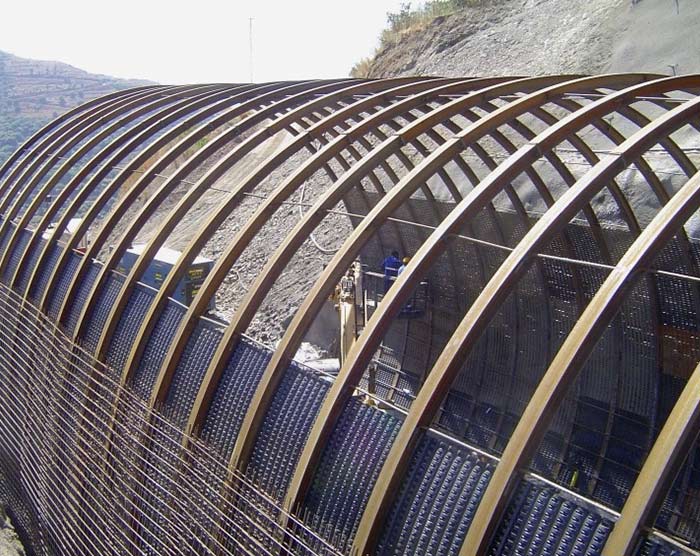

Support arches

Metal support arches are used in a wide range of applications and with many different soil conditions, offering the advantage of being resistance to compression and traction efforts with a high bending moment. This support technique is suitable for soil conditions that are very prone to subsidence due to the efforts caused by converging soils.

Cold curved beams are used to adapt to the excavation diameter, using the radii required to install them in parallel to the soil. Our entire manufacturing process, from design, bending, welding and dispatch, is certified by:

EN-1090 (CE marking) yand governed according to the ISO9001 quality system.

Rigid “HEB” support arches

High-resistance beams that maintain the cross-section dimensions with a low deformation or in which the decompressed soil thickness around the tunnel must be limited within strict parameters. The sectors are joined to form the entire arch using bolted joints between the plates.

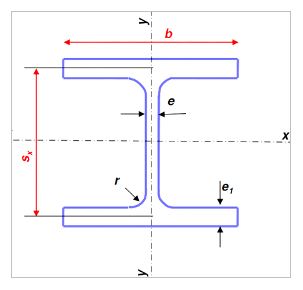

Characteristics of HEB beams

| TYPE OF BEAM | DIMENSIONS | CROSS-SECTION | WEIGHT (kg/m) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| h | b | e | e1(mm) | Ix (cm4) | Wx (cm3) | Iy(cm4) | Wy (cm3) | ||

| HEB 100 | 100 | 100 | 6 | 10 | 450 | 90 | 167 | 33 | 20,4 |

| HEB 120 | 120 | 120 | 6,5 | 11 | 864 | 144 | 318 | 53 | 26,7 |

| HEB 140 | 140 | 140 | 7 | 12 | 1509 | 216 | 550 | 79 | 33,7 |

| HEB 160 | 160 | 160 | 8 | 13 | 2492 | 311 | 889 | 111 | 42,6 |

| HEB 180 | 180 | 180 | 8,5 | 15 | 3831 | 426 | 1363 | 151 | 51,2 |

| CHARACTERISTICS OF HEB BEAMS | |||

|---|---|---|---|

| STEEL QUALITY | S275JR | EN10025 | >275 N/mm |

| STEEL QUALITY | S355JR | EN10025 | >355 N/mm2 |

The beams in the table show the most common dimensions used for support elements, although these can be manufactured up to HEB280. The dimensions and bend radius are usually indicated under the customer’s needs and requirements, although our highly-qualified technical office has a vast experience in designing and manufacturing the optimum beam in terms of resistance and weight/metre ratio.

THN Sliding support arches

Support arches manufactured with a THN omega beam. The THN beam has a high transversal inertia momentum in terms of weight per metre. The sectors are placed one on top of the other (overlapping) and they remain joined by two flanges or clamps. These frames are subject to deformation, caused by their assembly. The slipping resistance depends on how tight the clamps are. This type of arches combine the high resistance of metal support elements with the sliding properties of the arch, which give way when the soil pressure reaches a certain value, preventing failure in the arch. Another of the main benefits is its simple and quick installation, as well as adapting better to the excavated section.

These can be curved inversely, upon special order, a system that is commonly used in tunnels executed in civil works projects.

Standard cross-sections are used, but the radii and sectors are usually specified by the customer. Our highly-qualified technical office has a vast experience in designing and manufacturing the optimum beam in terms of resistance and weight/metre ratio.

Characteristics of TNH beams

| TYPE OF BEAM | DIMENSIONS | CROSS-SECTION | WEIGHT (kg/m) | ||||||

|---|---|---|---|---|---|---|---|---|---|

| h | b | e | e1(mm) | Ix (cm4) | Wx (cm3) | Iy(cm4) | Wy (cm3) | ||

| THN 16,5 | 106 | 90 | 44,25 | 13 | 173 | 38 | 227 | 43 | 16,7 |

| THN 21 | 127 | 108 | 54 | 12 | 324 | 60 | 410 | 64 | 21 |

| THN 29 | 150,5 | 124 | 58,2 | 16 | 616 | 94 | 775 | 103 | 29 |

| THN 36 | 171 | 138 | 66,8 | 17 | 969 | 136 | 265 | 149 | 36 |

| CHARACTERISTICS OF SUPPORT ARCHES WITH THN BEAMS | |||

|---|---|---|---|

| STEEL QUALITY | 31Mn4 | EN21544 | >350 N/mm |